In the debut episode of Beyond Point to Point, host Joe Greek is joined by Averitt’s own Mark Davis, Greg Hallmark, and Jason Brewer to explore the upcoming NMFC changes and what they mean for shippers. From pricing structures and freight measurement to packaging best practices, this episode breaks down the key steps shippers can take now to prepare for this major industry shift.

Watch the Full Episode:

Key Takeaways:

-

NMFC changes in 2025 will simplify classification and shift more products to density-based rating.

-

Freight accuracy—including weight and dimensions—is more important than ever for avoiding unexpected charges.

-

Packaging matters: cutting corners to improve density can lead to damage, claims, and lost customers.

-

Averitt’s tools and training help shippers get ahead of these changes, including our online density calculator and expert guidance.

If you have questions about how these updates might impact your business, reach out to your Averitt transportation specialist or visit averitt.com/NMFC.

Click Here to Read Full Transcript of This Episode of Beyond Point to Point

Narrator: Welcome to Beyond Point to Point, the podcast where we go beyond pickup and delivery and dive deeper into the world of logistics, freight, and supply chain management. From industry trends to expert insights, we're here to help you navigate the complexities of modern shipping. Be sure to subscribe to Beyond Point to Point wherever you watch or listen to your favorite podcasts. And now, here's your host, Joe Greek.

Joe Greek: Welcome to the very first episode of Beyond Point to Point. I'm Joe Greek, and I'm excited to kick off this podcast, where we'll explore the latest trends, challenges, and solutions in logistics and supply chain management. At Averitt, we know that moving freight is about more than just getting from point A to point B. There's strategy, innovation, and a lot of moving parts behind every shipment. That's why we created Beyond Point to Point, to go beyond the basics and dive deeper into the topics that matter most to shippers.

For our first episode, we're covering a major industry shift that's coming in July, the changes to LTL freight classifications under the NMFC. If you're in shipping, these updates could impact how your freight is classified and ultimately how it's priced. To break it all down, I'll be talking with experts who are on the front lines of these changes. We'll cover what's happening, what it means for shippers, and how to prepare. We'll also be heading over to our Cookeville Service Center to take a closer look at how accurate weight and density measurement plays a role in all of this, and of course, we'll be diving into how packaging choices impact freight protection, because cutting corners on packaging to cut cost could lead to bigger problems down the road.

It's going to be a packed episode with a lot of valuable insights, so let's get to the first point in today's route. To help us kick off this conversation, I'm joined by my very first guest on Beyond Point to Point, someone who knows this industry inside and out. Mark Davis is Averitt's vice president of Pricing and Traffic, and he's been part of the Averitt team for an incredible 46 years.

Well, Mark, thank you very much for being the first guest on Beyond Point to Point.

Mark Davis: My pleasure. Glad to be here.

Joe Greek: Well, you know, I've only been in the industry for about 10 years. I've seen my significant events and disruptions in the industry, the Amazon Effect, COVID, large carriers going bankrupt, even a very large cargo ship blocking the Suez Canal for a few days there, but I think over your career, you've seen some even bigger shifts, and what I'm really getting at is you got to experience deregulation in the early '80s. Could you kind of tell me what that was about and how it helped shape the industry as it is today?

Mark Davis: Yeah. Sure thing. Yeah, it was the Deregulation Act of 1980, and that deregulated rates and routes that had heretofore been super-regulated, where filings with the ICC were mandatory. So it became kind of the Wild West. And promptly after that legislation came the onset of discounting, that that was a foreign term and certainly nothing had ever been realized in our industry, and of course, it's still with us 40 plus years later at this point too.

So what we're talking about today on the change with the NMFC, I think it's got the potential to be the biggest change in LTL pricing since discounting. So 40 plus years, that's saying something.

Joe Greek: So we're not talking about coupon changes here, we're talking about some pretty significant shift. Could you give us a high-level overview of exactly what this is and what it means for shippers?

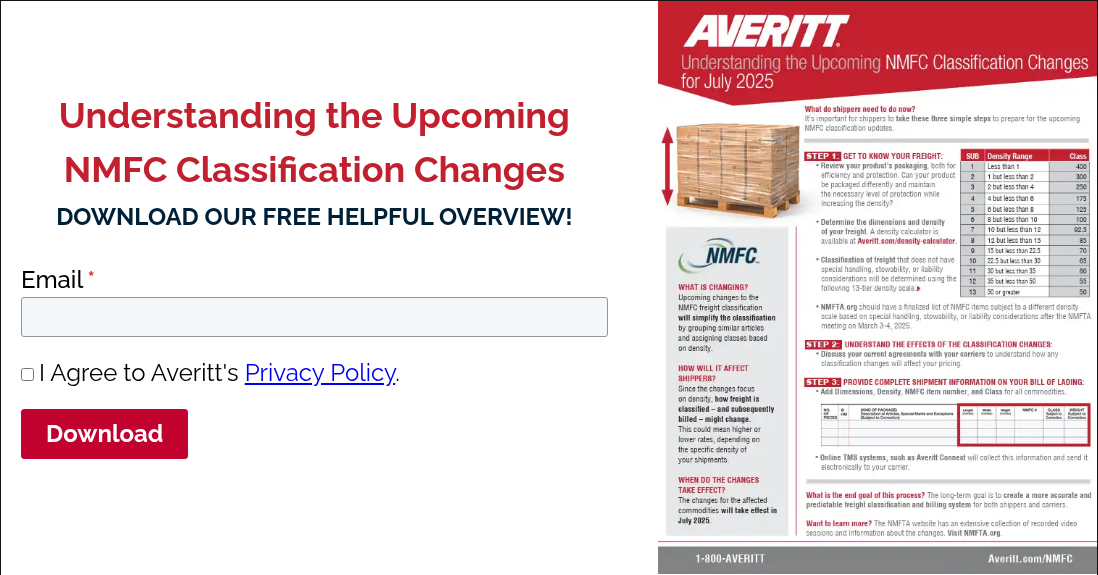

Mark Davis: Yeah, I can. The classification looks at four characteristics when coming up with a class for products, and that is density, which it should be density, density, density, and density, all four, but seriously, along with handling, stowability, and liability. So for years and years, decades, our customers, shippers have complained that the classification was too complex, too complicated, and so what's going on with the NMFTA now, it's kind of a decades-long response to this issue, so the NMFTA member, carriers, and staff have taken on this simplification initiative. So that's what it's about. And what the outcome primarily will be is where the simplification comes in.

More and more, if not most commodities will become density-related solely in those other three factors for consideration, handling, stowability, and liability. As long as they don't have a significant impact on a commodity, they're to the wayside. So simplification is coming.

Joe Greek: That's great. So it sounds like there's a big benefit for carriers and shippers by simplifying the whole process, correct?

Mark Davis: I certainly believe so. The big question, though, is, "What does it mean for me? If I'm a shipper, what does it mean for me?" And the simple answer is it depends, because all of these class ratings had the potential for change, just given what their actual density is. So each commodity will be rated off of a 13-subprovision scale, depending on what the density is.

Joe Greek: So with that, I think the big question on shipper's mind is, "How is it going to impact pricing?" And so how would you go about explaining that to shippers today?

Mark Davis: Well, first of all, they got to know their freight. That's the first thing. And unfortunately, many shippers aren't that sophisticated to have that knowledge, but they need to know what the density of their freight is, and I mean, density as packaged for shipping. And Averitt, we have tools on our website. We have a density calculator on our website that can walk our customers through that.

Joe Greek: Well, Mark, you've seen a lot of things over your career. So what are the most common mistakes that shippers make with freight classifications?

Mark Davis: Inaccurate information on the bill of lading, and whether it's a bad weight or the wrong description. And so the description and the weight and the handling units are important, but in addition to those, what we're coming up with now, we need the dimensions. We need the length, the width, and the height. With the weight, then of course, we can calculate the density. But if they have the NMFC item in their freight class, supply that as well.

It may need corrected, but the more information and the best accuracy possible that they can give us is the mistake not to make.

Joe Greek: So it really comes down to getting to know your freight.

Mark Davis: Absolutely.

Joe Greek: Well, we've got this big shift coming in July. Are there any changes in the future for the LTL industry that you're aware of or that shippers need to be thinking and planning ahead for beyond just the NMFC changes?

Mark Davis: Well, first of all, the NMFC project, it will continue. And just like today's current process, it's ongoing because new products come into the market, new packaging, new compositions, so that process will keep going. But because of the focus on density, and because carriers have invested in dimensional scanners, that, I believe, will proliferate more even into the shippers' hands on shippers' docks. But what I think it will morph to is more in different pricing formats that are based on dimensions and density outside of the old freight class. For instance, Averitt, our exact rate is a dimensions-based rating product today.

So whether units could be charged in Pounds or Dollars per cubic foot, we have the ability to do that now, but I think there's going to be an acceptance when more of this information on dimensions and density becomes more mainstream.

Joe Greek: Well, you're obviously the man with a wealth of knowledge on the subject of everything LTL, and I really appreciate you joining me today on the show, and I look forward to having you on again in the future.

Mark Davis: Well, thank you, Joe. I appreciate it.

Joe Greek: Thank you.

Mark Davis: Glad to be here.

Narrator: Averitt has been delivering success for over half a century with passion, pride, and a powerful network. Introducing The Power of One, your single source for transportation and logistics. Our comprehensive services include LTL, Truckload, Dedicated, Distribution & Fulfillment, and Integrated Global Solutions, but what truly sets us apart is our people, dedicated to serving you. For any need, local or global, trust Averitt, The Power of One.

Joe Greek: Now, we've talked a lot about freight classification, but another big part of this conversation is making sure shipments are measured accurately. For our next point, we're heading over to our Cookeville Service Center to get our hands dirty. Well, hopefully not too dirty, and we'll take a closer look at how weight, dimensions, and density play a role in these upcoming changes, so buckle up. Welcome back. We're at the Averitt Service Center in Cookeville, Tennessee. We're miles down the road from our corporate headquarters and centralized call center.

Each day, thousands of shipments move in and out of facilities like this across our distribution network. They're originating and destined for locations across the south, across the country, and across the borders with Canada and Mexico, and even around the world. Our next guest is Greg Hallmark. He is our area way and research leader. Let's go inside and meet him. Greg.

Greg Hallmark: Joe, how are you, man?

Joe Greek: It's good to see you today. Thanks for making the trip up from Birmingham.

Greg Hallmark: Yeah, enjoyed it.

Joe Greek: Thank you. Well, let's go discuss NMFC changes and density.

Greg Hallmark: Well, let's go. All right.

Joe Greek: All right. It's a pleasure to have you on the show. With the upcoming NMFC changes in 2025, why does this matter more than ever for shippers?

Greg Hallmark: One of the main reasons is there's going to be a lot of the freight that was not density-rated that will be density-rated now. I figure there'll probably be around 1,800 to 2,000 different items in the NMFC that will be density-rated. And for our shippers, it's going to be imperative that they get the correct weight and the correct measurements on the bill of lading at that particular time. Now, for most of our customers, well, really for all of them on the bill of lading, they are required to list an actual NMFC, the actual weight, and the actual class. With the new, I guess, densities coming into place, it would also be beneficial for them to put the actual measurements on the bill of lading as well also.

Joe Greek: So one of the things that comes up a lot in LTL operations is reweighing of freight. So why does that occur, and can you walk us through the process?

Greg Hallmark: Well, one of the reasons that it occurs is, say we have a shipper that does not have scales, they do know what their product weighs, and they put it at like an even three or 400 pounds and the actual shipment weighs 10 to 1,200 pounds, we would be taking a major loss on it. Now, if it's something that's a low class, a low density, that's not that big of a deal, but say it's something like a stepladder or packing peanuts, where it's a class 300 or 400, that's going to be a major deal, and all we're doing is protecting our own profits. Now, from a customer standpoint, if we don't get the weights correct and we say we cut a trailer out here, then it says it weighs 37,000 pounds, and it runs across the scales of any of these state lines and it weighs 57,000 pounds because of incorrect weights, we're the ones that's going to have to pay for that, not the customer. So we've got to make sure, for our own equipment, for our own safety, and for our own profitability that the weights are correct. There are instances where we have shippers overstate the weight.

When they overstate the weight, most of the time, if it's a large enough weight difference, we'll cut that weight back and actually save the customer that much money.

Joe Greek: Well, I would assume that most of the time, it's generally going to be a mistake when people are reporting their weights and classifications. So what are the most common mistakes that a shipper makes that you see day-to-day?

Greg Hallmark: Really, it's not so much as mistakes. The majority of our shippers really do try to do the right thing and put the correct weights on. Some of them will have a book weight, and they know exactly what their products weigh, where it's product A, product B, product C, and they may have a warehouse full of different products, but they know on a computer screen exactly what that particular product weighs, and they put down on the bill of lading what that product weighs and say it's on two or three pallets. Well, we've also got the weight of the pallet and the packaging that we need to put into place there. And the majority of the time, that's the biggest mistake that I see, is they don't factor in what we call the tare weight.

Other times is where we'll have bill of ladings that we pre-print for a particular customer where it has an FAK, which means Freight All Kinds, and they've got certain parameters that they go by and what they're billed at, and say it's a class 100. Say they're billed at a class 100, that's what they'll put on the bill of lading regardless of what class the freight actually is. And sometimes when we look at it, when we measure it, when we get the densities on it, it does not fall under that parameter, and we actually make a class change on that. But the weight is probably nine times out of 10. We do 20 weight changes for every one class change that we do, because we have scale lifts, we have floor scales, and they are accurate within 1%, because if they're not accurate within 1%, we can't even use them.

And 1% would be 10 pounds for every 1,000 pounds weighed, so that would be your 1%. So they're accurate within 10 pounds for per 1,000 pounds.

Joe Greek: Well, I think you've illustrated how important it is to get the measurements and classifications correct. Would you be willing to show us how to go about measuring an actual pallet of freight out on the dock?

Greg Hallmark: All right. Absolutely. Sure.

Joe Greek: All right.

Greg Hallmark: Let's go right now.

Joe Greek: Let's go. All right. Well, now we have some freight to measure. Would you mind giving us the walkthrough?

Greg Hallmark: Well, first thing we do, of course, we walk around the freight and make sure there's no damage visible, whatsoever, then we take length times width times height. Now, when we do the length times width times height, we have to measure it from longest point to longest point. Sometimes we have shippers that put a cone on top, but it says, "Do not stack." Well, we'll have to measure to the top of that cone, or sometimes we'll have shippers that'll have an oversized pallet. Well, we have to measure the pallet, and if the freight overhangs, then we have to measure the freight, whichever one is longest point to longest point.

And in this case, it's going to be the pallet. So we'll go down through here. So it's 44 by 36 by 48, and then we'll write that down. We'll record that down. Now, how we figure the densities on this, we'll take the length times width times height, multiply that all together, and then we'll divide that number by 1,728, where we get 1,728 is 12 times 12 times 12, which is how many cubic inches are in a cubic foot.

Say this one comes out to 50 cubic feet. Then we'll take the weight, and we'll say that it's 600 pounds, and we'll divide 600 pounds by the cubic footage. So 600 divided by 50 would be 12, so the density of this pallet would be 12 pounds per cubic feet. Now, on a density scale, you're looking at anywhere from a class 400 all the way down to a class 60. So depending on where that falls, say 12 pounds per cubic foot would fall between 12 and 15, which would be a class 85. So this particular shipment would be a class 85, and that's how we figure that up.

Joe Greek: And if you're not an expert at math like myself, you can also go on averitt.com/density-calculator to input your numbers to get the actual density as well to help speed up the process.

Greg Hallmark: Yes, yes. All you need to know is the measurements of your shipment and the weight of your shipment. You can put that into our calculator, and it will figure the density for you.

Joe Greek: Great. And we'll show how that works. All right. Now that we're on the Averitt website, we can get to the Density Calculator. So when we're here, we can put in the number of pieces for the shipment, which was one, then we can put in the length, which was 44 inches, then we can do the width, which was 36 inches, and then we can do the height, which was 48 inches.

Finally, we'll put in the weight, which we said was 600 pounds. Now that we've put those points in, we can calculate it. Now, we have our measurements at 44 cubic feet with a density of 13.64. Now that we've shown how this tool works, we've got to get back over to the studio to talk to our last guest, Jason Brewer.

Narrator:

Voted the number one LTL carrier by shippers nationwide. You can always count on Averitt's industry-leading low claims and superior transit times. For over 50 years, we've been your trusted transportation partner, dedicated to saving you time and money. From standard LTL to guaranteed service, we've got your supply chain covered. Experience professionalism with 24/7 customer support and real-time tracking at your fingertips.

No matter the size or frequency of your shipments, whether regional, national or cross-border, we offer flexible and reliable LTL solutions under one roof. Averitt, that's The Power of One.

Joe Greek: All right. We're back in the studio for our final point, and I've got a great guest to close things out. Joining me now is Jason Brewer, Averitt's loss prevention leader. Jason has been with Averitt for nearly 30 years, which means he's seeing just about everything when it comes to keeping freight safe and damage-free. With these NMFC changes coming, we know some shippers may be tempted to cut costs down on packaging to improve their density and lower costs, but as Jason will tell us, that can lead to some expensive problems down the road.

Jason, thank you very much for coming on the show today. First question I want to ask you, "What are the actual hidden costs of reducing packaging practices to improve density?"

Jason Brewer: Oh, that's a very good question, Joe. One that I'm very passionate about, in fact, I've seen it in action, where less packaging equals more damage and more reduction of quality customer service. In fact, I would say that in LTL, packaging is probably one of the most important controlled variables that we can manage in an ever-changing LTL transportation world that can create a successful delivery. Whenever we start removing packaging or maybe even trying to configure it in a way, maybe it's to reduce pricing on density, but it could also be because they're trying to reduce packaging pricing. Ultimately, the shipper is responsible for packaging the commodity since they're the expert in the commodity, and then everything that the carrier does is in order to prevent any occurrences to affect that type of packaging in a negative way.

What happens is the NMFC starts the conversation by outlining the minimum standards of packaging that include general specifications, but also commodity-driven requirements as well that have been deemed to best protect that product. That's the minimum, though. So a customer may still have to add additional packaging in order to protect what may be more prone to being damaged based on whatever that specific commodity is. If not packaged to meet those standards, then a carrier could ultimately decline a claim. So you have that cost, but it doesn't just stop at the claim.

Even if the carrier filed or actually paid the claim, and there still is an increase in damages or shortages, the shipper risks losing sales, they risk dissatisfied customers, increased back orders, then increased production costs, and then increased freight costs, and eventually maybe, when capacity tightens up, carriers aren't going to want to accept their freight for transportation, because in essence, there's some liability there.

Joe Greek: Well, it really does sound like a double-edged sword when you're thinking of compromising standard packaging procedures just to potentially reduce some costs. So packaging is obviously very important in our industry, and at Averitt, we move freights of all kinds. We move LTL, we move full truckloads, we also move ocean cargo containers. So could you give me some of the biggest maybe packaging misconceptions when you're thinking of LTL versus truckload? Is there a difference in the way people need to go about packaging their freight?

Jason Brewer: Yeah. Actually there are two recurring conversations that we have with our customers from the loss prevention or a claim standpoint, and one is that a lot of customers believe that they received their freight just fine in the packaging that it's in. "Why can't I just put it on one of your trucks and the packaging be fine for that leg of transportation?" Well, most likely, that packaging was designed to be loaded most efficiently in a container or a truckload, or maybe even a flatbed, where it's not going to come into contact with unlike freight stacked tightly against it. And so it probably would ride along just fine in those transportation legs, but in LTL, it's completely different, because like I was mentioning, there's so many other different types of freight that could potentially make contact, or even the physics in the rear of the trailer, along with that unlike freight could cause unforeseen opportunities that packaging needs to be able to protect from.

Joe Greek: When it comes to LTL distribution, what does the actual process of freight and transit look like? What is occurring inside the trailer from pickup to final delivery?

Jason Brewer: Well, that's a good question, Joe. To be a piece of freight in the back of the trailer could be very frightening. I only say that because you're surrounded by so many pieces of unlike freight. It's not just our customer's one type of product that's in the back of the trailer. And as it moves down the road, it's experiencing a lot of rigors, such as freight shifting forward, shifting backwards, taking curves, taking turns, hitting potholes, a constant vibration.

I've been behind a trailer, where it's going down the highway, and you can actually just see the rear end of the trailer just constantly bouncing. And, of course, I had my kids with me. I was like, "Look, kids. Look what that does." But the important thing is that we understand that our customer's freight, or my freight is not the only freight in the back of that trailer, from pickup to relay, to delivery, while we're cross-docking it.

LTL is a fast-paced industry where cut times are important. We have to hurry sometimes, and we also use a lot of tools, that if the packaging isn't proper, then even the tools that we use to try to protect the freight could end up damaging it.

Joe Greek: Well, that is actually very fascinating, and just considering all the physics that are occurring inside the trailer from the point-to-point through the entire duration of the freight's journey. So given that you have all these variables within the journey, when you're speaking with shippers, what are some of the damage prevention tips that you give them that they should be employing in their everyday shipping practices?

Jason Brewer: Well, yeah. If they focus on packaging and the different elements of packaging and understand what that means, that packaging isn't just ... This is providing a way for us to move it in and out of the trailer, but in LTL, the purpose of packaging is to protect the freight. It doesn't have to be pretty. You don't have to have your emblem all over it to make it protect freight, but you do have to have the product covered, and that wouldn't need to be rigid material, which could be what?

Cardboard, composite material, plywood. It would need to be rigid enough to withstand some type of impact. A well-built crate offers the most protection. Then also, then you move on to the interior packaging. Once you know what your outside packaging is like, then you get interior packaging that's going to protect from any shock, vibration, compression, or crushing.

Think about a fiberboard box. You have your product in there. There's a lot of stacking in LTL, like we've discussed, and you'll want some protective interior packaging that will keep that void space upright, where it will be filled and not collapse when something is stacked on it. Next, we'd have to move to, "What's the foundation like?" Right?

We want the foundation to be in a good order. We want the pallet or the skid should be right size. It should be in good condition. By right-sized, I mean you don't want anything overhanging. Some of the overlength freight, you want one solid, right-sized foundation.

You don't want to have two different pallets on a long piece of freight, because one of those pallets, more than likely, will be torn off as a result of that. You want your deck board spacing to be narrow enough, and you want it to be, the support to be strong enough that your product doesn't fall through the spacing, but also, when we're using our forks that something doesn't come up from underneath and cause damage to the undercarriage of that product. It may be tempting to make the pallet or skid shorter because that may help your density a little bit, or it may help the volume that you can place on the pallet, or be able to increase weight with product, and that could change the density. But when you do that, when you have a shorter pallet, you risk ... Okay.

Our drivers use a pallet jack to unload freight. Well, suddenly, we can't get our pallet jacket underneath that. How are we going to unload it off of our trailer? So a standard four to six-inch pallet is better than trying to reduce down to a shorter pallet in order to gain some type of savings on freight, if your ultimate goal is customer satisfaction. And then also, it would be tempting to narrow the footprint of the pallet as well, because if you narrow the footprint and your weight is high, and you can add more freight on that, then that changes your density to a higher density.

And what that will do is it could create a top-heavy product, or your pallet is suddenly top-heavy. You really need a wider base whenever you have taller freight. So those things have to be taken into consideration. Finally, the product has to be secured. So many times, we see product all wrapped nicely with plastic, but it's just sitting on top of the pallet, and those inertias and physics that we were talking about earlier, that's going to slide that freight right off the pallet, and we're going to have to recover from that.

Hopefully it's not damaged after it does that. So you want to make sure the wrap actually overlaps the pallet, probably about a couple layers over three inches at least, over the pallet itself, and using banding. You want to make sure it's banded in all directions.

Joe Greek: At Averitt, we're very proud to have a industry-leading low claims ratio. We have great partnerships with our shippers. We work very closely with them, but at the same time, there's an internal element in how we train our associates to also handle freight. So could you tell us a bit about what Averitt does internally to protect our shipper's freight?

Jason Brewer: Yeah. Thanks for asking that, Joe, because I think it's very impressive myself because we get better and better at it the more we do it. And our leadership out in the field, they do a tremendous job, making quality a priority, and associates understand that, that, "Hey, my leader wants this to be a priority for them, and that means it's a priority for me," and we take that seriously at Averitt. And what's interesting to me is that whenever we're talking to customers about improving their packaging, that's one thing they bring up. They're like, "Well, if my packaging is so bad for LTL, why don't I ever experience damages, other than periodically?"

And that's when we get to brag. We get to say, "Hey, you're absolutely right." You don't experience a lot of damages, but that doesn't mean your packaging is bad for LTL. Every load is different in LTL. We invest in our teams.

We do that in training and coaching. We do that in ... They're vested. And if the claims ratio is low, if the quality is good, they understand that we need to have good quality, so that way, our customers will want to stay with us through thick and thin. They use a variety of tools.

We invest in airbags. We buy cardboard. We buy a lot of straps. We have load bars. We have pallet decks that we invest in to reduce the stacking opportunity.

All those things that we do on the dock using those tools and using them properly, and holding each other accountable through photo feedback, and coaching, and learning from each other, mentoring each other on the dock, those things are the things that make us great.

Joe Greek: Well, thank you very much for giving us a little insight on what's happening behind the scenes at Averitt. And I think this conversation was just very informational and very insightful for our customers and shippers throughout the industry, and I really appreciate the time you gave me today.

Jason Brewer: Yeah. Thanks for having me, Joe.

Joe Greek: Thank you very much. Now, let's take a step back and recap what we covered today. We kicked things off with Mark Davis, who broke down the upcoming NMFC classification changes and what shippers need to know. Then, we took a trip to our Cookeville Service Center to talk with Greg Hallmark about why accurate freight measurement is more important than ever. And finally, Jason just walked us through the hidden risk of cutting corners on packaging and how shippers can protect their freight.

These changes are coming fast, and shippers who prepare now will be in the best position to avoid surprises. If you have questions about how these updates might impact your business, reach out to your Averitt transportation specialist, or visit averitt.com/NMFC. And with that, we're wrapping up the very first episode of Beyond Point to Point. If you found this conversation helpful, be sure to subscribe wherever you enjoy your favorite podcasts, and we'll catch you next time.