A major distributor within the beer and beverages industry with operations across Texas and neighboring states, specializing in leading brands like Modelo, Miller, and Coors, along with additional products, including marketing materials. Their mission aligns closely with Averitt’s commitment to professionalism, efficiency, and fostering strong partnerships.

This case study highlights how Averitt provided customized, scalable supply chain solutions to support the distributor’s expanding operations while maintaining exceptional service quality and reducing operational costs.

The Challenges:

-

Capacity Issues: Managing fluctuating demand in various distribution centers, particularly in rural markets, strained internal resources.

-

Acquisitions and Infrastructure: Recent acquisitions in regions like Del Rio TX required innovative solutions to maintain operations without additional investment in facilities.

-

Cost Efficiency: Balancing competitive logistics costs while ensuring high service standards remained a key challenge.

-

Complex Distribution Needs: Managing delicate and high-volume beverage distribution for diverse product lines, including bottles, cans, kegs, and marketing materials, across multiple locations.

Initial Engagement:

Averitt began with local customization runs, transporting beer and beverages to locations like Victoria, Midland-Odessa, and McAllen TX. This initial partnership laid the foundation for an expanded relationship.

WHAT IS LOCAL CUSTOMIZATION?

Local Customization reflects Averitt’s commitment to providing flexible and creative transportation solutions tailored to each customer’s unique needs. Recognizing that standard regional less-than-truckload services may not fit every situation, Averitt offers a range of specialized services designed to address specific, localized logistical challenges, including:

-

Local Warehousing and Storage: Secure storage options to accommodate varying inventory needs, providing flexibility in supply chain management.

-

Same-Day Cross-Town Cartage: Expedited local deliveries to meet urgent shipping requirements within the same day.

-

Night and Weekend Pickups and Deliveries: Extended service hours to align with customers’ schedules and reduce operational disruptions.

-

Trailer Switching and Milkruns: Efficient handling of multiple pickups and deliveries, optimizing routes and reducing costs.

-

Plant-to-Plant Deliveries and Warehouse Moves: Streamlined relocation services for equipment and inventory between facilities.

-

Local Expedited or “Hot Shot” Runs: Rapid-response deliveries for time-critical shipments.

Dedicated Solutions:

-

Developed a dedicated two-driver run from San Antonio to Victoria, Del Rio, and back.

-

Leveraged Averitt’s San Antonio distribution center for cross-docking and storage.

-

Supplemented the distributor’s fleet during peak demand periods, providing reliability and scalability.

Del Rio: A Strategic Partnership for Efficiency

Following the acquisition of a family-owned distributor in Del Rio, the distributor closed the brick-and-mortar location to reduce overhead costs.

Averitt’s Del Rio cross-dock facility enabled them to:

-

Retain local drivers from the acquired business, ensuring continuity and supporting local employment.

-

Provide access to facilities, including parking, breakrooms, and an office leased for administrative support.

-

Efficiently handle cross-docking, returns, and temporary storage, with most products moving out within four to five hours.

Flexible Operations:

-

Adapted to customers’ needs with linehaul services, cross-docking, and on-call capacity for one-off delivery requests in rural markets like Cuero and Yoakum TX.

-

Supported returns and handling of out-of-date products, aligning with the distributor’s operational goals.

The Results:

Improved Efficiency

-

Eliminated the need for the distributor to maintain their own facility in Del Rio, significantly reducing overhead costs.

-

Optimized delivery routes for high-demand products, ensuring timely service.

Enhanced Customer Experience

-

Positive feedback on Averitt’s clean equipment, professional drivers, and effective communication.

-

Proactive handling of weather delays and schedule adjustments minimized disruptions.

Cost Savings & Growth Potential

-

Delivered cost-effective logistics solutions that complemented the distributor’s operations.

-

Positioned Averitt as a trusted partner for future expansions, such as new acquisitions in Oklahoma City and Shreveport.

Key Differentiators:

Partnership-Oriented Approach

-

Averitt established strong relationships with the distributor’s key stakeholders, fostering trust and collaboration.

-

Delivered exceptional service that emphasized quality and reliability, providing great value compared to competitors.

End-to-End Solutions

-

Provided warehousing, linehaul, and final-mile delivery, ensuring seamless operations at every stage.

-

Supported cross-docking, returns management, and temporary storage needs.

Driver Excellence

-

Drivers consistently praised for their professionalism, dependability, and ability to integrate with the distributor’s team.

-

Clean, dependable equipment and first-class image reinforced the distributor’s brand standards.

Conclusion

Averitt continues to strengthen its partnership with the distributor, identifying new opportunities for collaboration in San Antonio and beyond. This case study exemplifies how Averitt’s flexible solutions, professional culture, and dedication to customer success create a competitive edge within the beer and beverages industry.

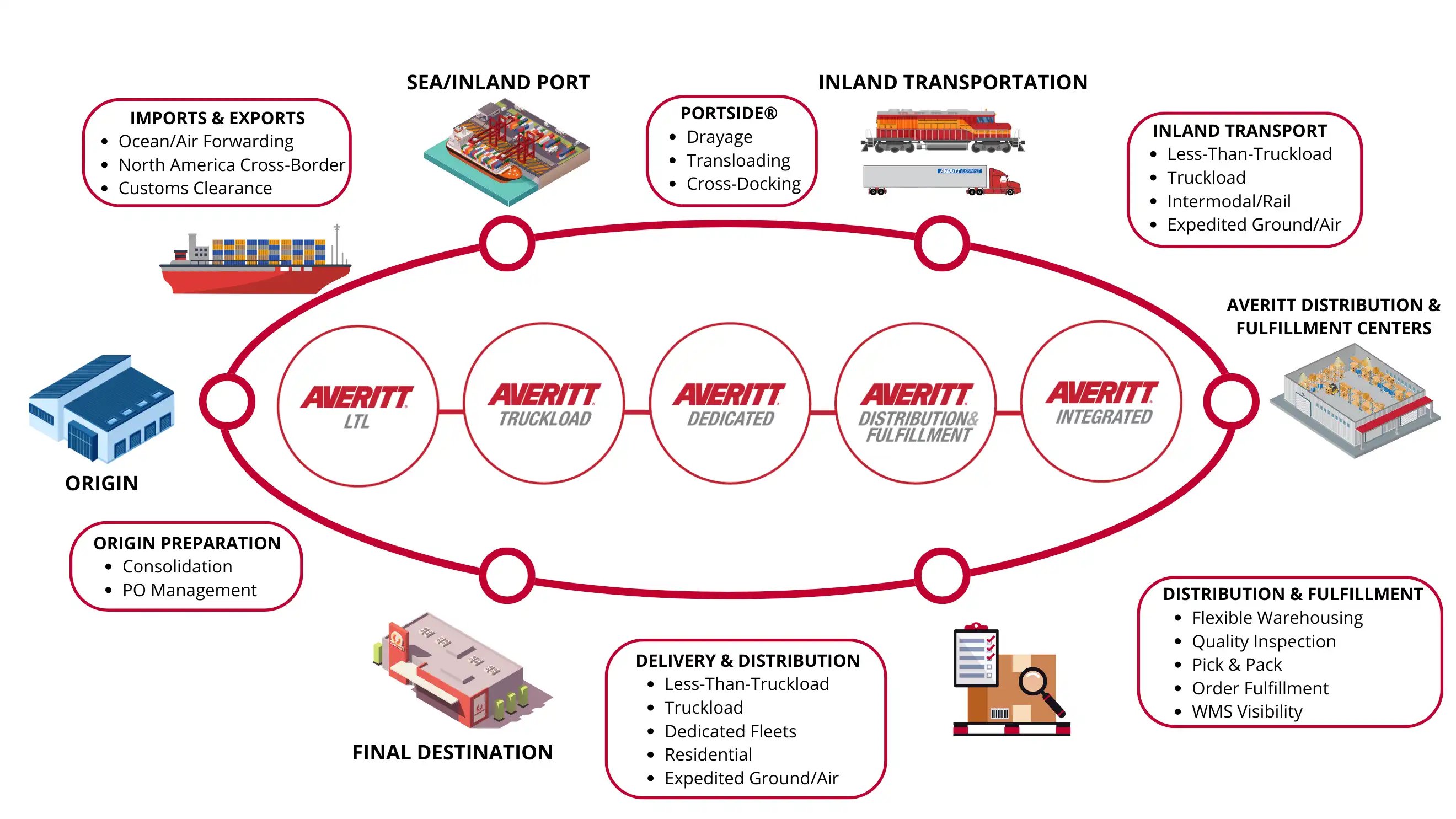

The Power of One

At Averitt, our Power of One approach means every aspect of your supply chain is supported by a single, trusted logistics partner. From transportation and warehousing to inventory management and final-mile delivery, we provide end-to-end solutions tailored to your business needs. With one contact and 24/7 customer support, you gain the simplicity, reliability, and responsiveness that only an integrated, asset-based provider can deliver.

Watch the short video below to learn more about our Power of One Approach!