The call to innovate is louder than ever. With every new supply chain disruption—global unrest, port congestion, labor shortages, shifts in sourcing—companies are under pressure to “transform” their logistics strategy. But in this rush, many overlook a fundamental truth: innovation isn’t always about building something new.

Sometimes, it’s about seeing what you already have from a different angle.

At Averitt, we call this rethinking the wheel instead of reinventing it.

Innovation Stagnation: When Movement Isn’t Progress

We often associate stagnation with standing still. But in logistics, stagnation can look like doing more without getting better. Adding systems. Adding tools. Adding providers. But still facing the same bottlenecks, the same charges, the same gaps in visibility or performance.

This kind of innovation stagnation happens when we chase newness instead of asking: “Could the systems we already have be working better?”

Reinvention Isn’t the Only Way Forward

You don’t need to scrap your supply chain strategy to make real improvements. In fact, many of the biggest wins come not from reinvention—but from re-evaluation.

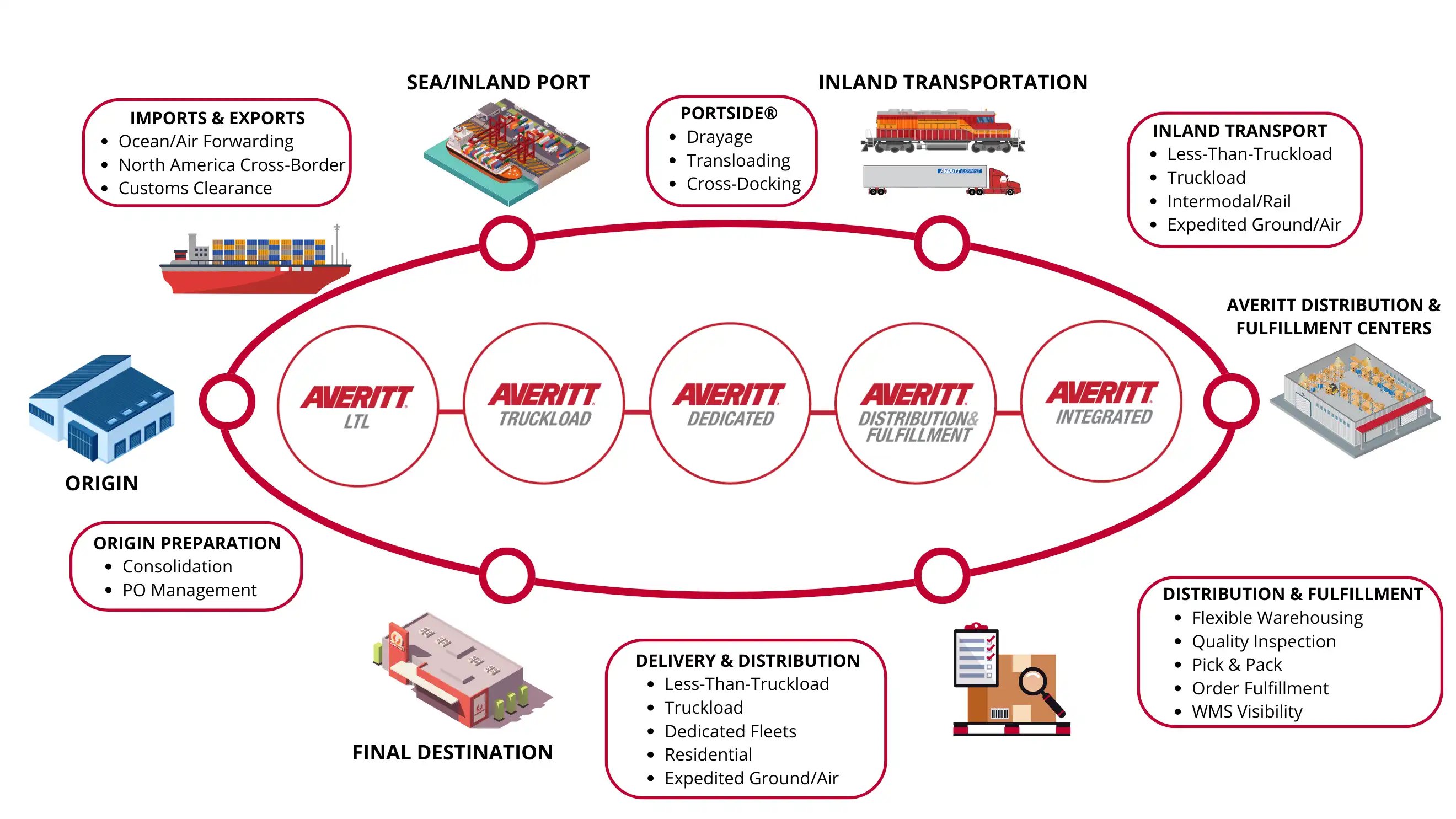

Take inbound cargo, for example. For years, many shippers have moved freight through West Coast ports like Los Angeles/Long Beach, then relied on rail services to move it inland to distribution centers in the central U.S. That model can still make sense, especially when you're serving a large concentration of customers near your DC. But for others, it's time to step back and ask whether the existing routing still aligns with where customers actually are.

We’ve worked with shippers who, out of habit or history, rail everything to a central warehouse in the middle of the country—yet most of their customers are in the Southeast or Mid-Atlantic. That means every order requires extra miles, more fuel, more transit time, and more trucking costs.

When companies rethink their inbound flow—from sourcing and port of entry to where inventory is staged—they can often reduce transportation costs significantly, improve delivery speed, and eliminate costly extras like demurrage and detention.

Rethinking Market Proximity: A Hidden Efficiency Lever

One of the most overlooked opportunities in modern supply chain strategy is aligning where your inventory lands with where your customers are.

If your inbound cargo is routed through the West Coast and railed to a central location like Oklahoma—but the majority of your customer base is in the Carolinas, Georgia, or Virginia—you may be spending far more on inland transportation than necessary.

By shifting the inbound strategy to flow through East Coast ports like Savannah or Charleston, and staging inventory at warehouses, shippers can:

- Reduce inland trucking miles by positioning product closer to end markets

- Avoid detention and demurrage fees that often stack up at congested West Coast terminals

- Gain faster access to inventory with more flexible outbound shipping

- Adapt to demand shifts more fluidly across regional markets

- Improve sustainability within your supply chain by reducing overall trucking miles

It’s not about abandoning your infrastructure. It’s about realigning it to better match your market footprint.

With the right partner, inventory can move directly from the port to a nearby transload or Distribution and Fulfillment Center, then out the door via asset-based truckload or LTL—streamlining the entire cycle and freeing up capital locked in inefficiency.

Efficiency Is the New Innovation

The most resilient companies aren’t those that chase disruption. They’re the ones who optimize relentlessly—who find efficiency not just in what they add, but in what they can simplify, realign, or cut.

And efficiency can come from surprising places:

- Reducing handoffs between brokers and carriers

- Moving consolidation points closer to origin ports

- Streamlining communication across internal departments

- Leveraging existing infrastructure more strategically

These changes don’t require a “new system.” They require a new perspective.

See Your Supply Chain Differently

The good news? You don’t have to figure this out on your own.

Averitt has been helping companies take a fresh look at their supply chains for more than 50 years. With an asset-based LTL and truckload network, integrated international and customs capabilities, and a growing network of Distribution and Fulfillment Centers at key U.S. ports, we’re helping enterprise shippers rethink what’s possible—without starting from scratch.

We’re not here to sell disruption. We’re here to help you optimize what you already have.

What’s Working? What’s Not? What Could Work Better?

These are the questions forward-thinking logistics leaders should be asking today. Because in a world where macroeconomic and geopolitical factors are out of your control, your supply chain doesn’t have to be.

There is always opportunity—sometimes hiding in plain sight.

It’s not about building a new wheel. It’s about rethinking how you use the one you already have.

Are you ready to rethink your supply chain? Contact our team today by filling out the form below to get the wheel moving.